Recent advances in temperature sensor technology include improved accuracy, miniaturization, and integration with IoT for real-time monitoring and data analytics.

Temperature sensor technology has undergone radical transformation in recent years. Today’s sensors are smaller, more accurate, and packed with smart features that enable real-time monitoring across industries. From manufacturing floors to smart homes, these advancements are changing how we measure and respond to temperature changes.

Cutting-Edge Temperature Sensor Innovations

Modern temperature sensors now incorporate several groundbreaking technologies:

- Wireless IoT connectivity for remote monitoring

- Ultra-miniaturized designs for space-constrained applications

- Self-calibrating capabilities for long-term accuracy

- Energy harvesting to eliminate battery changes

- AI-powered predictive analytics

IoT-Enabled Smart Sensors

The integration of wireless protocols like Bluetooth Low Energy (BLE) and Zigbee has revolutionized temperature monitoring. Smart thermostat controls now leverage these sensors to optimize energy use in homes and businesses. Industrial facilities deploy wireless sensor networks across equipment to prevent overheating and predict maintenance needs.

Example: Manufacturing Floor Monitoring

A leading automotive manufacturer implemented wireless temperature sensors across their production line. The system:

| Metric | Improvement |

|---|---|

| Equipment downtime | Reduced by 37% |

| Energy consumption | Decreased by 22% |

| Product defects | Dropped by 15% |

Specialized Sensor Applications

Temperature sensing technology has diversified to meet specific industry needs:

Medical Grade Precision

Hospitals now use ultra-accurate sensors for patient monitoring and vaccine storage. Some models achieve ±0.1°C accuracy – critical for sensitive medications. Amphenol Advanced Sensors leads in this space with FDA-approved medical devices.

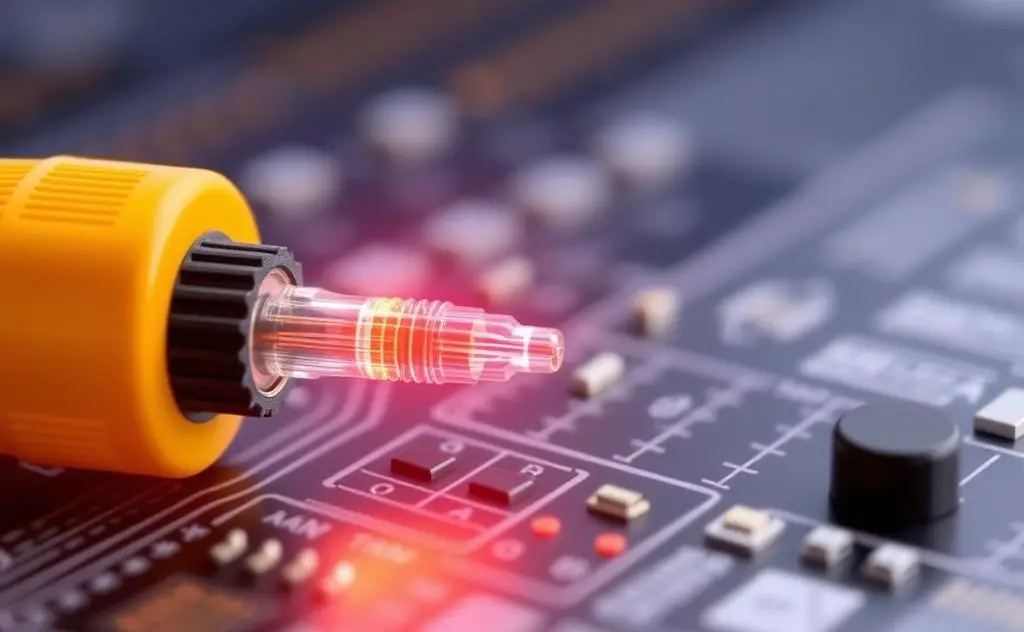

Extreme Environment Solutions

New materials enable sensors to function in previously impossible conditions:

- Ceramic-based sensors for high-temperature industrial processes (up to 1500°C)

- Fiber optic sensors for corrosive chemical environments

- MEMS (Micro-Electro-Mechanical Systems) for vibration-prone applications

The Future of Temperature Sensing

Emerging technologies promise even greater capabilities:

- Self-powered sensors using thermal energy harvesting

- Quantum temperature sensors with unprecedented accuracy

- Flexible, printed sensors for unconventional surfaces

- AI-enhanced predictive maintenance systems

These advancements complement other smart home technologies like modern electric heaters that blend efficiency with aesthetic appeal.

As research from the University of West of Scotland shows, sensor networks will become increasingly vital for Industry 4.0 implementations. The integration of temperature data with other operational metrics enables truly smart factories where systems self-optimize based on real-time conditions.