Choosing a heater used to be simple. You picked the warmest one for the cheapest price. Today, it’s a design statement. The materials in a contemporary heater dictate not just its performance, but its entire characterhow it looks, feels, and integrates into your living space.

Modern heater materials are selected for a blend of function and form. They must manage heat efficiently, ensure safety, and look good doing it. For a perfect example of this balance, consider the Dreo Space Heater. Its design often features a sleek stainless steel or aluminum body paired with advanced internal components, showcasing how material choice directly impacts heater build quality and user experience.

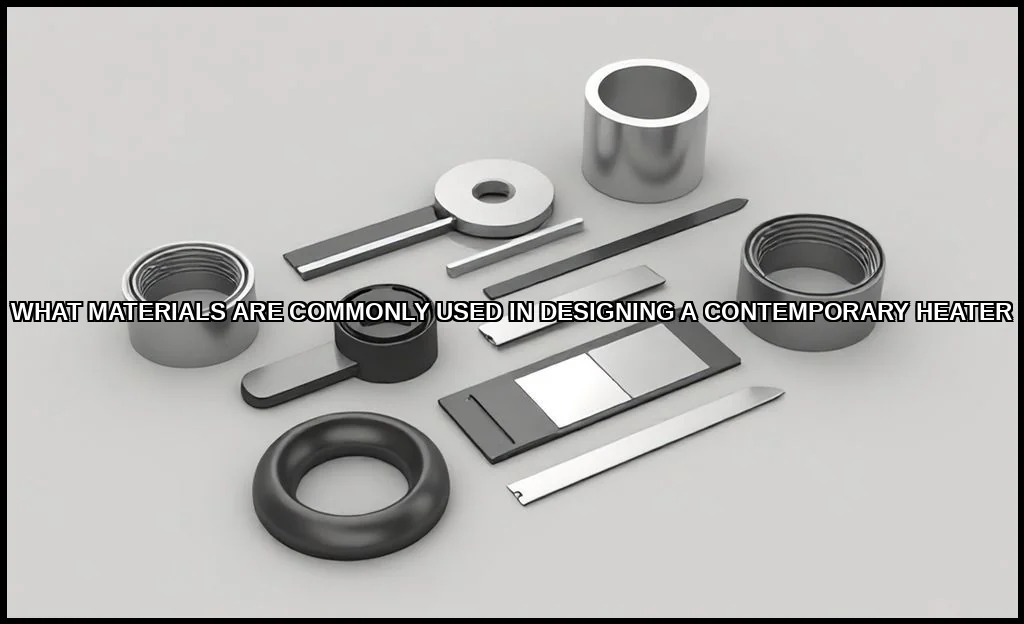

The Role of Materials in Modern Heater Design

Every component in a heater has a job. The core elements generate warmth. The casing contains and directs it. Surfaces manage safety and aesthetics. This synergy defines contemporary heating design. You’re not just buying a heat source; you’re choosing an appliance built from specific efficient heating materials for a specific purpose.

Material properties like thermal conductivity, emissivity, and specific heat capacity are the unsung heroes. They determine how quickly a heater warms up, how evenly it distributes heat, and how much energy it uses. The right combination elevates a simple appliance into a reliable, efficient home feature.

Core Structural & Heating Elements: Metals and Alloys

This is the engine room. Metals form the skeleton and the heart of most heaters, prized for their strength and ability to manage high temperatures.

Aluminum and Its Alloys

Aluminum is a superstar in electric heater construction. It’s lightweight, has excellent thermal conductivity, and resists corrosion. You’ll find it in thin, finned designs for convection heaters and as housings for ceramic heating elements. Its ability to dissipate heat quickly makes it ideal for fast-acting space heaters.

Stainless Steel

When durability and a modern finish are paramount, stainless steel steps in. It offers superior strength and a corrosion-resistant, easy-to-clean surface. This makes it the best metal for a modern space heater casing that needs to look pristine for years. Its use speaks directly to material durability in high-traffic areas.

Copper and Brass

These traditional favorites are still used in specific radiator materials and plumbing connections for hydronic systems. Copper’s unmatched conductivity makes it efficient for transferring heat from water or electric elements. You often see it in the internal tubing of premium oil-filled radiators.

Curious about how hot these systems can get? For a related look at temperature limits in water-based systems, check out what the maximum operating temperatures are.

Aesthetic & Safety Surfaces: Glass, Ceramic, and Composites

These materials define the user interface. They are the touchpoints you see and interact with, and they must be both beautiful and safe.

Tempered Glass

Tempered glass is a cornerstone of modern fireplace materials. It can withstand significant thermal stress, allowing for a clear view of realistic LED flames while staying cool to the touch. The quest for the perfect glass front fireplace heater materials almost always ends with high-quality, safety-tempered glass. It transforms a heater into a focal point.

Advanced Ceramics

Beyond the heating element, ceramics are used for casings and surrounds. A common question is, what is the casing of a ceramic heater made from? Often, it’s a molded ceramic composite or a ceramic-coated metal. This provides excellent heat resistant materials properties, keeping the exterior safe while the interior glows hot.

Engineered Composites and Plastics

High-temperature plastics and composites like PBT (Polybutylene Terephthalate) are workhorses. They’re used for grilles, control panels, and structural housings where electrical insulation and weight savings are critical. They enable the sleek, minimalist forms popular in current space heater design.

Material Selection by Heater Type

Different heating technologies demand different material strategies. Heres how it breaks down across common categories.

Infrared Heaters

The materials used in infrared heater design focus on efficient emission. The heating element is typically a quartz tube or a carbon fiber filament, chosen for its ability to emit infrared waves. Reflectors made of polished aluminum or stainless steel are placed behind the element to direct the radiant heat forward, maximizing efficiency.

Ceramic Heaters

The namesake ceramic heating elementa positive temperature coefficient (PTC) ceramicis key. It self-regulates, reducing overheating risk. The casing is often aluminum to pull heat away from the ceramic core, paired with a plastic outer shell for insulation and safety. This combination is a masterclass in functional designer heater finishes.

Oil-Filled Radiators

These are all about thermal mass. The body is typically constructed from welded steel columns, which are filled with diathermic oil. The steel provides structural integrity and a large surface area for passive convection. The finish is usually a powder-coated paint, which is durable and comes in various colors. For a deep dive into a trusted brand in this space, our review explores how good Bradford White units perform.

Modern Electric Fireplaces

This is where material science meets interior design. A combination of tempered glass, metal (often powder-coated steel or aluminum), and sometimes realistic ceramic logs or stones creates the illusion. The frame might use MDF with a wood veneer or laminate for a built-in look. Its a holistic approach to fireplace materials.

| Heater Type | Core Heating Material | Primary Casing Material | Key Material Property Utilized |

|---|---|---|---|

| Infrared Heater | Quartz Tube / Carbon Fiber | Polished Aluminum, Steel | High Emissivity, Reflectivity |

| Ceramic Heater | PTC Ceramic Element | Aluminum Fins, Engineering Plastic | Self-Regulation, Thermal Conductivity |

| Oil-Filled Radiator | Diathermic Oil, Steel Columns | Powder-Coated Steel | Thermal Mass, Durability |

| Electric Fireplace | LEDs, Heater Fan | Tempered Glass, Metal Frame | Heat Resistance, Aesthetic Versatility |

Future Trends: Sustainable and Smart Materials

The next wave is already here. Sustainability is moving from a buzzword to a specification. Recycled aluminum and steels are becoming more common in electric heater construction. Biodegradable composites for non-critical parts are on the horizon.

Smart materials are even more intriguing. Imagine a heater casing with integrated phase-change materials that store excess heat and release it later. Or surfaces with dynamic finishes that change color with temperature. The integration of these materials will further blur the line between appliance and architectural element.

For the latest thinking on efficient home heating technologies and systems, the Department of Energy serves as an excellent official source for research and guidelines.

Bringing It All Home

Your choice in a heater is fundamentally a choice in materials. That sleek silhouette is possible because of advanced polymers. The instant, focused warmth comes from precisely engineered ceramics and metals. The safe, cool-touch surface is a feat of glass or composite engineering.

Look beyond the wattage and the thermostat. Check the product descriptions for the materials used. Feel the weight and finish. A heater built with thoughtful material selection promises not just warmth, but lasting performance, safety, and style. It becomes a seamless part of your home’s ecosystem, not just a seasonal gadget. Thats the real power of modern contemporary heating design.