Temperature sensors in HVAC systems monitor and regulate indoor climate, ensuring efficient heating and cooling for optimal comfort and energy savings.

Temperature sensors are the silent heroes of HVAC systems, ensuring optimal climate control while maximizing energy efficiency. These precision devices continuously monitor air and water temperatures, allowing your heating and cooling systems to respond dynamically to environmental changes. From residential smart homes to massive commercial complexes, proper sensor selection and placement can make the difference between wasted energy and perfect comfort.

Critical Roles of HVAC Temperature Sensors

Modern HVAC systems rely on temperature sensors for three fundamental operations:

- Precise climate control within ±0.5°F accuracy

- Energy optimization through demand-based operation

- Equipment protection against extreme temperatures

According to Belimo’s HVAC sensor research, properly calibrated sensors can reduce energy consumption by up to 18% in commercial buildings. This makes them essential for meeting modern thermostat control standards and sustainability goals.

Primary Sensor Types in Modern Systems

1. Averaging Temperature Sensors

These workhorses measure temperature across large spaces or duct sections:

| Feature | Benefit |

|---|---|

| Multiple sensing elements | Eliminates hot/cold spots in large zones |

| 10-50 foot sensing lengths | Ideal for auditoriums and open offices |

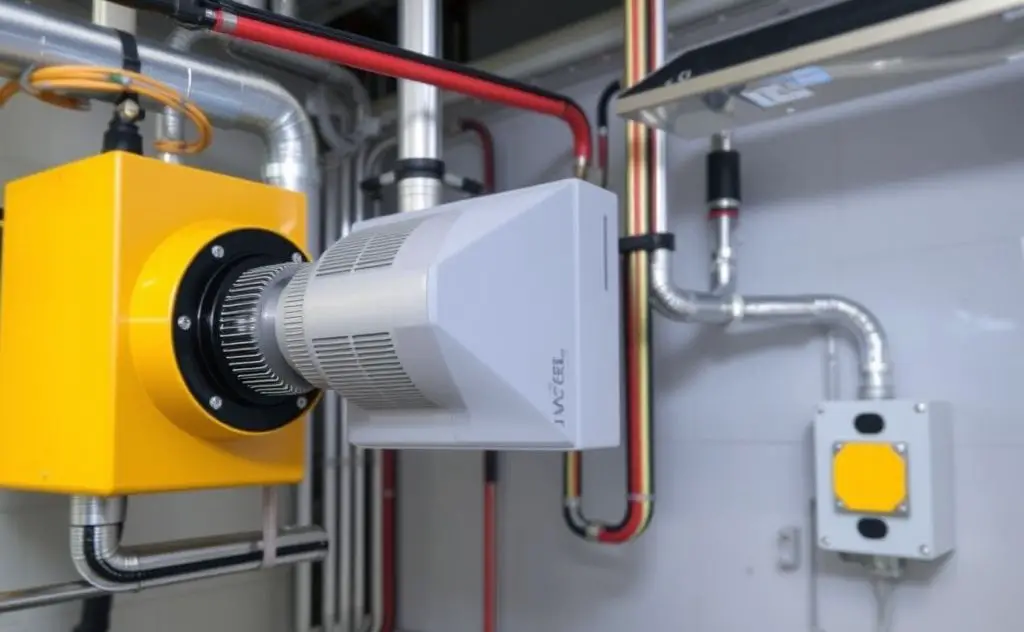

2. Duct Immersion Sensors

Critical for air handling units, these sensors:

- Mount directly in airflow streams

- Respond within 30 seconds to temperature changes

- Withstand velocities up to 4,000 FPM

3. Liquid Immersion Sensors

Essential for hydronic systems, these heavy-duty sensors feature:

- 316 stainless steel or Incoloy sheaths

- Pressure ratings to 600 PSI

- Accuracy within ±0.25°F

Advanced Sensor Technologies

Modern HVAC systems increasingly utilize smart sensors with:

- Wireless connectivity for retrofit applications

- Self-diagnostics and drift detection

- Integration with app-controlled systems

The latest innovation comes from Belimo’s Room Sensors, which combine temperature, humidity, and CO2 monitoring with NFC configuration via smartphone.

Installation Best Practices

Proper sensor placement dramatically affects performance:

- Mount averaging sensors at 5′ height for occupant comfort

- Place duct sensors 10 duct diameters from bends

- Immerse liquid sensors fully in turbulent flow areas

- Avoid mounting near heat sources or cold drafts

Maintenance and Calibration

Regular sensor maintenance ensures ongoing accuracy:

| Interval | Action | Tolerance |

|---|---|---|

| Quarterly | Visual inspection | N/A |

| Annually | Field verification | ±1°F |

| Biennially | Full calibration | ±0.5°F |

Modern sensors with auto-zero functions, like those from Belimo, maintain accuracy longer between calibrations by automatically adjusting every ten minutes.

Integration With Building Automation

Advanced sensors now feed data to:

- Demand-controlled ventilation systems

- Predictive maintenance algorithms

- Energy dashboards for facility managers

This integration is particularly valuable when combined with decorative heating elements in commercial spaces, where both aesthetics and performance matter.