An oil-fired boiler functions by burning oil in a combustion chamber to heat water, which is then circulated through pipes to provide heating and hot water, utilizing a burner, heat exchanger, and control systems for efficiency and safety.

Oil-fired boilers provide reliable heating for homes and businesses without access to natural gas lines. These systems burn heating oil to produce hot water or steam for radiators, baseboards, or radiant floor systems. Understanding how they function helps with maintenance and efficiency.

Oil Boiler Components and Operation

An oil-fired boiler consists of several key components working together:

- Oil storage tank – Holds fuel (typically kerosene or gas oil)

- Fuel pump – Delivers oil to the burner

- Combustion chamber – Where oil burns at high temperatures

- Heat exchanger – Transfers heat from combustion gases to water

- Circulation pump – Moves heated water through the system

The Heating Process Step-by-Step

- Oil travels from storage tank to burner via fuel line

- Nozzle atomizes oil into fine mist for efficient burning

- Ignition system lights the oil-air mixture in combustion chamber

- Heat exchanger absorbs thermal energy from hot combustion gases

- Circulating pump moves heated water through pipes to radiators

- Cooled water returns to boiler to be reheated

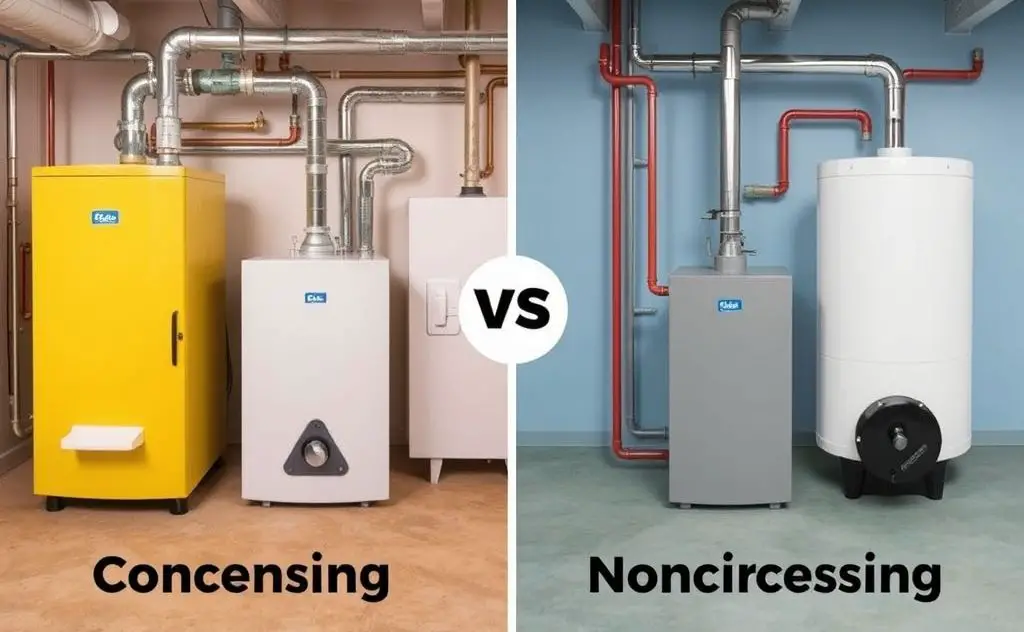

Condensing vs. Non-Condensing Oil Boilers

| Feature | Condensing | Non-Condensing |

|---|---|---|

| Efficiency | 90-95% | 80-85% |

| Heat Recovery | Uses waste heat from flue gases | Loses heat through exhaust |

| Cost | Higher initial cost | Lower purchase price |

| Lifespan | 15-20 years | 10-15 years |

Condensing models recover additional heat from water vapor in exhaust gases, making them significantly more efficient. The common issues with oil-fired boilers differ between these two types.

Fuel Storage and Maintenance

Proper oil tank installation and maintenance is critical for safety and performance:

Tank Installation Requirements

- Minimum 42mm thick concrete base extending 300mm beyond tank

- Fire wall required if within 1.8m of buildings

- Double-walled tanks recommended for leak prevention

- Vent pipes must extend outside and above ground level

Maintenance Tips

- Inspect tank monthly for leaks or corrosion

- Keep tank at least 1/3 full to prevent condensation

- Schedule annual professional cleaning of burner and heat exchanger

- Replace fuel filters regularly

- Consider adding boiler treatment to prevent sludge buildup

Efficiency and Environmental Impact

Modern oil boilers must meet minimum 86% efficiency standards (A+ rating). Key factors affecting efficiency:

- Proper burner adjustment and air-fuel mixture

- Clean heat exchanger surfaces

- Insulated pipes and tanks

- Modern control systems with weather compensation

While oil boilers produce CO2 emissions, they can be more efficient than some propane heating systems when properly maintained. The UK government plans to phase out new oil boiler installations by 2035 as part of carbon reduction goals.

Oil Consumption and Operating Costs

Average oil boiler fuel usage depends on:

- Home size and insulation quality

- Number of radiators or heating zones

- Thermostat settings and usage patterns

- Boiler age and efficiency rating

A typical UK home uses about 1,700 liters annually (17,000 kWh). During winter months, consumption averages 2.36 liters daily when running 6 hours per day (0.39 liters/hour).

For comparison with other systems, see our guide on oil-filled radiators vs electric heaters.

Professional Servicing Requirements

Annual maintenance by an OFTEC-registered technician should include:

- Combustion efficiency testing

- Heat exchanger cleaning

- Burner nozzle replacement

- Fuel filter inspection

- Safety controls check

- Flue gas analysis

Never attempt to open the combustion chamber yourself – this requires specialized tools and training. Improper maintenance can void warranties and create safety hazards.