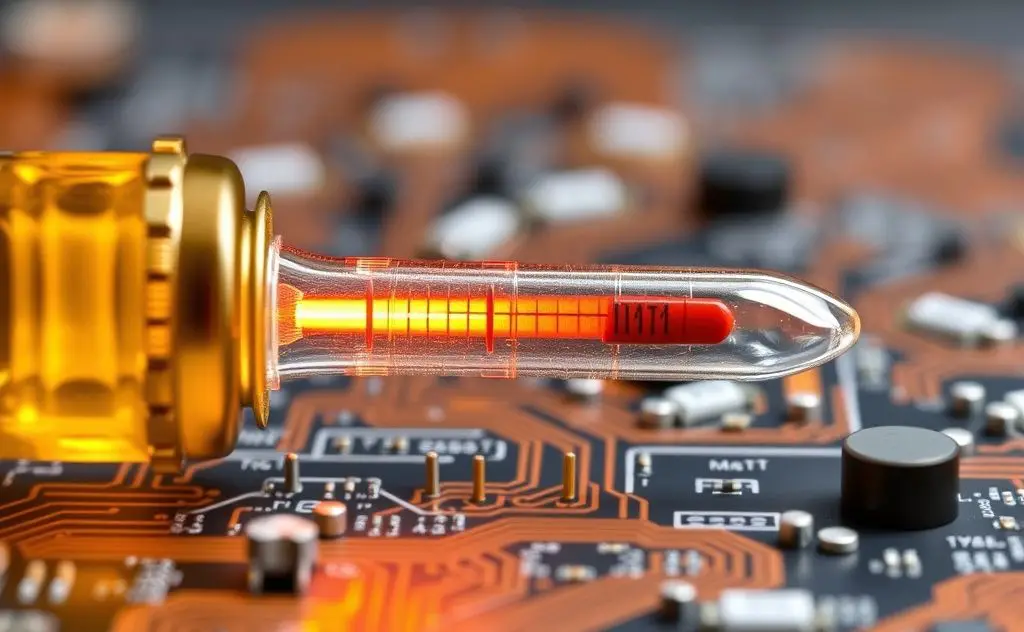

Temperature changes can affect the conductivity, resistance, and structural integrity of electronic materials, potentially leading to performance issues or failure.

Temperature fluctuations significantly impact electronic materials, altering their conductivity, structural integrity, and performance. From expanding metal bonds to degrading semiconductors, heat plays a crucial role in electronics reliability. Understanding these effects helps engineers design better devices for extreme environments.

Thermal Effects on Metal Components

Metal components in electronics experience both instantaneous and permanent changes when exposed to temperature variations. Research shows aluminum wire bonds subjected to temperature swings between 40°C and 70°C develop microstructural damage over time.

Wire Bond Degradation

Studies using 3D x-ray tomography reveal:

- Interfacial cracks near stress concentration points

- Inter-granular fractures along crystal boundaries

- Void formation within bond interiors

These defects accumulate during thermal cycling, eventually leading to failure. The damage progression differs between initial (“first”) and secondary (“stitch”) bonds in electronic packages.

Copper Beryllium Alloy Behavior

Alloy 25 HT (C17200 TH04) demonstrates how temperature affects mechanical properties:

| Property | Low Temp Behavior | High Temp Behavior |

|---|---|---|

| Yield Strength | Stable near room temp | Decreases rapidly above 150°C |

| Elastic Modulus | Maintains stiffness | Drops significantly at high temps |

| Elongation | Changes rapidly at room temp | Stabilizes at elevated temps |

Polymer-Based Electronics at Extreme Temperatures

Researchers at Purdue University developed breakthrough polymer blends that maintain performance from -40°C to 220°C. This innovation addresses a critical limitation of conventional electronics.

Material Composition

The blend combines:

- A charge-transporting semiconductor polymer

- A high glass-transition temperature insulating polymer

The optimal 1:1 ratio creates an interpenetrating network that preserves electrical properties across temperatures. For reliable temperature control in heating systems, similar material considerations apply.

Performance Characteristics

Key advantages include:

- Hole mobility exceeding 2.0 cm²/Vs

- Stable charge transport up to 220°C

- Minimal performance variation across range

These properties make the material ideal for built-in heating systems and automotive sensors near exhaust components.

Practical Applications

Temperature-stable electronics enable new possibilities across industries:

Automotive and Aerospace

Direct sensor mounting on hot engine components improves monitoring accuracy. Current systems require remote placement due to temperature limitations.

Extreme Environment Electronics

Devices can now function reliably in deserts, polar regions, and space applications where temperature swings are extreme.

Industrial Equipment

Manufacturing processes involving high heat can incorporate embedded electronics for better process control.

Future Research Directions

Scientists continue exploring:

- Lower temperature limits for polymer blends

- Alternative material combinations

- Scalable manufacturing processes

- Integration with existing semiconductor technologies

As noted in Purdue’s research, overcoming cold temperature challenges remains particularly difficult for organic electronics.

The Springer study on wire bonds demonstrates how advanced imaging techniques help understand thermal degradation mechanisms at microscopic levels.