The Importance of Calibrating High-Temperature Sensors

Significance of Accurate Temperature Measurement

Calibrating high-temperature sensors is like fine-tuning a musical instrument before a concert. Just as a musician needs to hit the right notes for a flawless performance, accurate temperature measurement is crucial for the optimal functioning of your water heater. Without proper calibration, your sensor might be playing the wrong tune, leading to potential issues down the line.

Common Issues with Uncalibrated Sensors

Picture a compass pointing in the wrong direction – that’s what happens when high-temperature sensors are left uncalibrated. Inaccurate readings can throw off the entire system, causing inefficiencies and malfunctions. Don’t let your water heater navigate blindly; ensure your sensors are calibrated to steer you in the right direction.

Benefits of Regular Calibration

Calibrating your high-temperature sensors is like giving them a health check-up. Regular calibration not only ensures accurate readings but also prolongs the lifespan of your sensors. It’s like maintaining a well-oiled machine; calibration keeps everything running smoothly and efficiently, preventing costly breakdowns in the future.

Impact on Data Accuracy

Imagine trying to solve a puzzle with missing pieces – that’s what it’s like when your sensors are not calibrated. Incomplete data leads to incorrect conclusions and decisions. Calibrating your high-temperature sensors ensures that your data is reliable and accurate, providing you with the full picture and empowering you to make informed choices.

Ensuring Safety and Efficiency

Safety should always be a top priority, especially when dealing with high temperatures. Calibrating your sensors is like installing a security system for your water heater, ensuring that it operates within safe parameters. Additionally, a well-calibrated system is more energy-efficient, saving you money in the long run in the course of reducing your environmental footprint.

Steps to Properly Calibrate High-Temperature Sensors

Discerning Sensor Specifications

Before diving into the calibration process, it’s crucial to grasp the intricate details of your high-temperature sensors. These specifications are like the blueprint of a building – without apprehending them, you might end up with a wonky structure that doesn’t serve its purpose.

Preparing for Calibration

Just like a chef gathers all the ingredients before whipping up a culinary masterpiece, you need to gather your tools and create a conducive environment for calibration. Picture yourself as a conductor preparing for a symphony – every instrument in its place, ready to create harmonious music.

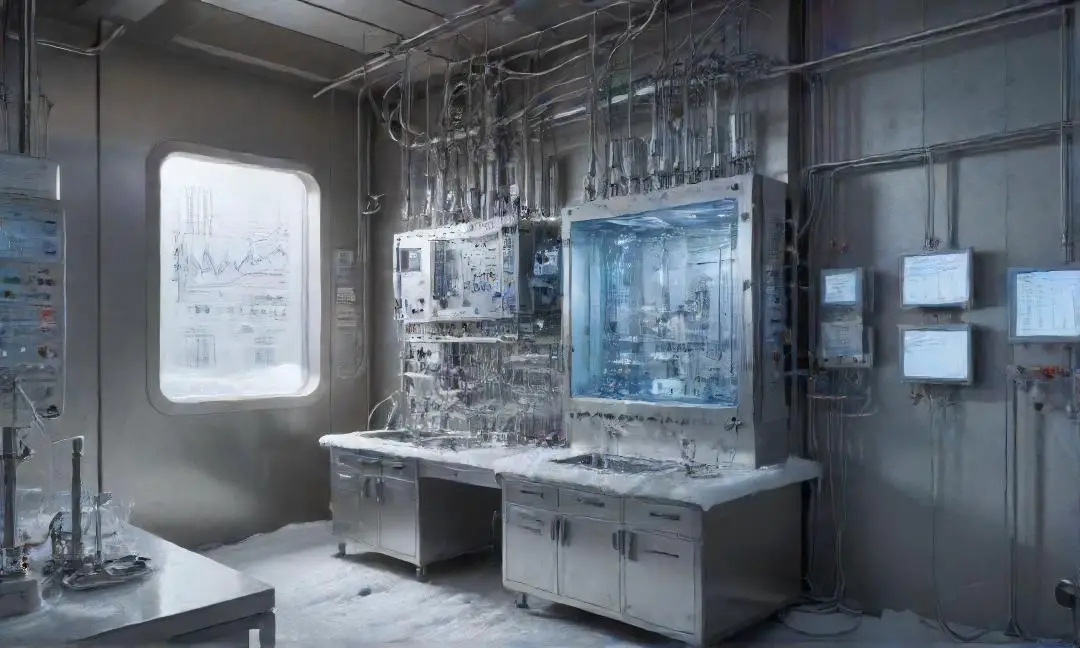

Using Calibration Equipment

Now it’s time to bring out the big guns – your calibration equipment. Think of yourself as a scientist in a lab, meticulously measuring and analyzing to ensure accuracy. Each tool is like a superhero in your arsenal, working together to save the day.

Adjusting Sensor Settings

As you probe into the nitty-gritty of calibration, it’s akin to being a detective solving a complex case. Every adjustment you make brings you closer to cracking the code and achieving precision. It’s a puzzle where each piece fits perfectly to reveal the bigger picture.

Verifying Calibration Results

Once the calibration process is complete, it’s time to cross-check and verify the results. Imagine yourself as a quality control expert, meticulously inspecting every detail to ensure that your high-temperature sensors are performing at their peak. It’s like the final exam where you double-check your answers before submitting.

Comparison of Calibration Techniques

As for calibrating high-temperature sensors, you have various techniques at your disposal. Each method offers unique advantages and limitations, so it’s crucial to compare them to determine the most suitable approach for your specific requirements.

Factors Influencing Method Selection

Choosing the right calibration method hinges on several key factors. Consider the accuracy needed, the sensor’s operating conditions, and the resources available for calibration. These aspects play a significant role in ascertaining the most effective approach for your high-temperature sensors.

Considerations for High-Temperature Environments

Calibrating sensors in high-temperature environments presents distinct challenges. Factors such as thermal stability, material compatibility, and heat dissipation must be carefully evaluated to ensure accurate and reliable calibration results. It’s essential to address these considerations to achieve optimal sensor performance.

Pros and Cons of Different Approaches

Each calibration method comes with its own set of advantages and disadvantages. In the course of some techniques offer precision and repeatability, others may be more cost-effective or easier to implement. Cognizing the pros and cons of each approach is crucial in making an informed decision for calibrating high-temperature sensors.

Recommendations for Optimal Results

For optimal calibration results, it’s recommended to combine multiple techniques or employ a hybrid approach. By leveraging the strengths of different methods, you can enrich the accuracy and reliability of sensor calibration. Additionally, regular calibration maintenance and adherence to best practices are essential for achieving consistent and precise sensor performance.

Identifying Calibration Errors

Spotting inaccuracies in sensor calibration is crucial for optimal performance. Begin by cross-referencing data against known standards. Look for deviations that may indicate calibration errors.

Addressing Drift Issues

Combatting sensor drift requires vigilance. Regularly monitor sensor performance over time to detect any gradual shifts in readings. Adjust calibration settings accordingly to maintain accuracy.

Dealing with External Interference

External factors can disrupt sensor calibration. Shield sensors from electromagnetic fields or other sources of interference. Ensure sensors are placed in a stable environment free from external disturbances.

Resolving Inconsistent Readings

Inconsistencies in sensor readings can be perplexing. Check for loose connections or environmental changes that may impact calibration. Recalibrate sensors to restore accurate readings.

Seeking Professional Assistance When Needed

When troubleshooting calibration challenges becomes overwhelming, don’t hesitate to seek expert help. Experienced professionals can diagnose complex issues and provide tailored solutions to ensure accurate sensor calibration.

Maintaining Calibration Records and Documentation

Importance of Record-Keeping

Starting off, let’s dive into why keeping meticulous records is crucial touching on calibrating your high-temperature sensors. Think of it as your sensor’s personal diary, chronicling its journey to accuracy and reliability. These records act as a roadmap, guiding you through past calibrations and helping you make informed decisions for future adjustments.

Best Practices for Documentation

Now, let’s talk about the art of documentation. Picture yourself as a detective, gathering clues to solve a mystery. Detailed notes, precise measurements, and clear observations are your tools in this calibration investigation. By heeding best practices, such as using standardized forms and capturing all relevant data, you ensure that no detail goes unnoticed.

Organizing Calibration Data

Imagine your calibration data as a puzzle waiting to be solved. Proper organization is the key to putting all the pieces together. Create a system that works for you, whether it’s a digital database or a color-coded filing system. Easy access to your data streamlines the calibration process and minimizes room for error.

Tracking Calibration History

Tracking the history of your sensor’s calibrations is like tracing its evolution over time. Each calibration builds upon the last, shaping the sensor’s performance. By maintaining a clear timeline of past calibrations, you gain valuable insights into trends, patterns, and potential issues that may arise.

Compliance with Industry Standards

As a final point, let’s touch on the importance of meeting industry standards. Think of these standards as the rules of the calibration game, ensuring fair play and accurate results. Adhering to these guidelines not only boosts your credibility but also guarantees that your high-temperature sensors are operating at their peak performance levels.

Implementing a Calibration Schedule for Long-Term Success

Establishing a Routine Calibration Plan

Initiating a consistent calibration schedule is pivotal in ensuring accurate sensor readings. By creating a detailed plan, you lay the foundation for reliable performance and precise measurements. Think of it as setting the stage for a symphony; each note must be finely tuned to produce harmonious music.

Setting Reminders and Notifications

Implementing reminders and notifications serves as your personal assistant, gently nudging you when calibration time approaches. These prompts act as friendly reminders, akin to a trusty alarm clock waking you up each morning, ensuring you never miss a calibration session.

Integrating Calibration into Maintenance Programs

Marrying calibration with your maintenance programs creates a seamless workflow that streamlines efficiency. It’s like intertwining two dance partners in perfect rhythm, where calibration becomes a natural extension of your routine maintenance, enhancing overall system performance.

Monitoring Sensor Performance Over Time

Regularly monitoring sensor performance provides valuable insights into any deviations or anomalies. It’s akin to keeping a watchful eye on a garden, observing how each plant grows and blooms over time. This vigilance ensures early detection of any issues, fostering a proactive approach to maintenance.

Continuous Improvement for Enhanced Reliability

Embracing continuous improvement practices guarantees enhanced sensor reliability. It’s like fine-tuning a classic car, where each adjustment refines its performance, ensuring optimal functionality. By consistently refining calibration processes, you pave the way for long-term success and unwavering accuracy.