The Impact of Temperature on Structural Materials

1. Temperature’s Influence on Material Properties

Temperature plays a crucial role in ascertaining the properties of structural materials. It can affect strength, ductility, and other mechanical characteristics, ultimately impacting the performance and longevity of the material.

2. Thermal Expansion and Contraction: A Closer Look

When materials are exposed to temperature changes, they expand or contract. This phenomenon, known as thermal expansion and contraction, can lead to issues such as warping, cracking, or dimensional instability in structural components.

3. Heat Treatment Techniques for Enhancing Material Performance

Heat treatment is a process used to alter the physical and mechanical properties of materials by heating and cooling them in a controlled manner. This technique can improve hardness, toughness, and overall performance, making materials more suitable for specific applications.

4. Addressing Thermal Stress in Structural Components

Thermal stress occurs when temperature variations cause internal stresses within a material. To prevent failure or deformation, it is essential to design structural components that can withstand these thermal stresses through proper material selection and design considerations.

5. Selecting the Right Materials for High-Temperature Applications

Choosing the appropriate materials for high-temperature applications is critical to ensure optimal performance and durability. Factors such as thermal conductivity, strength at elevated temperatures, and resistance to oxidation must be carefully considered when selecting materials for use in high-temperature environments.

Strategies for Mitigating Thermal Degradation in Materials

Insulation Solutions to Regulate Temperature Fluctuations

Isolating materials from extreme temperatures is crucial. Utilize advanced insulating materials to create a protective barrier against thermal fluctuations. This helps maintain stability and prolongs the lifespan of the material.

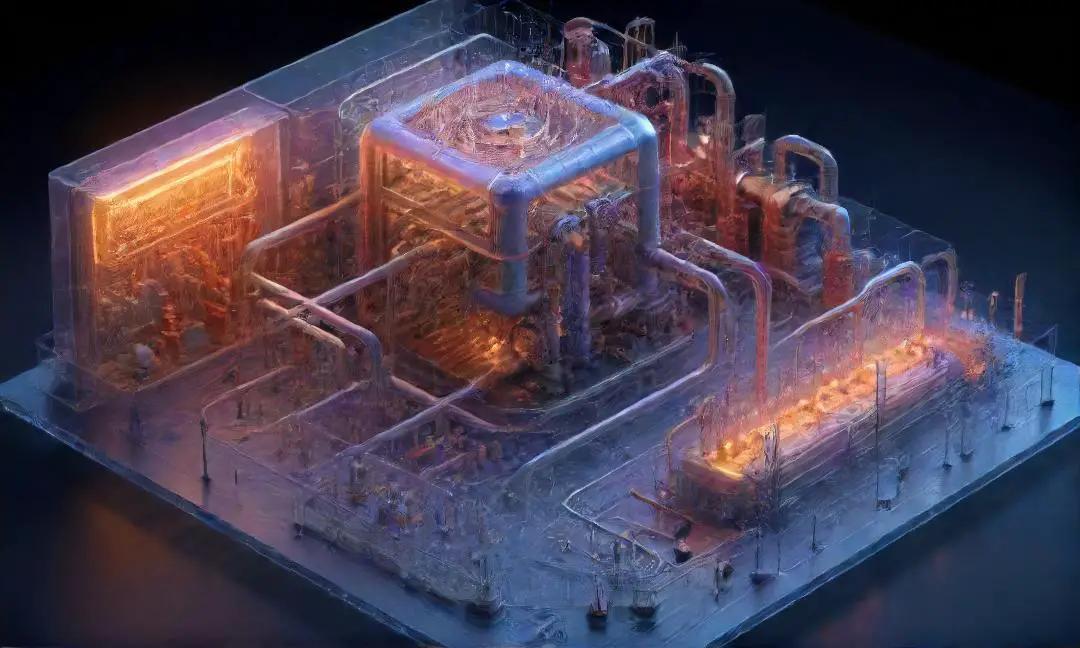

Cooling Systems: Maintaining Optimal Operating Conditions

Implement efficient cooling systems to counteract excessive heat buildup. By ensuring optimal operating conditions, you can prevent thermal degradation and enrich the overall performance of the materials.

Protective Coatings: Shielding Materials from Heat Damage

Apply specialized coatings to shield materials from heat damage. These protective layers act as a barrier, safeguarding against high temperatures and minimizing the risk of thermal degradation.

Design Considerations for Heat Dissipation

Integrate effective heat dissipation mechanisms into the material design. By strategically planning for heat dissipation, you can prevent overheating and maintain the structural integrity of the materials under varying temperature conditions.

Monitoring and Controlling Temperature Effects in Real-Time

Utilize advanced monitoring systems to track temperature variations in real-time. By actively monitoring and controlling temperature effects, you can promptly address any deviations and implement corrective measures to mitigate thermal degradation.

Case Studies: Successful Applications of Temperature Management

Aerospace Industry Innovations in Heat-Resistant Materials

The aerospace sector has been at the forefront of developing cutting-edge heat-resistant materials to withstand extreme temperatures experienced during space travel. These materials play a crucial role in ensuring the safety and reliability of spacecraft and satellites, pushing the boundaries of human exploration beyond the confines of Earth’s atmosphere.

Automotive Sector: Advancements in Engine Thermal Efficiency

Automobile manufacturers have been continuously improving engine thermal efficiency by coalescing innovative materials that can withstand high temperatures generated during combustion processes. These advancements not only augment performance but also contribute to reducing emissions, making vehicles more environmentally friendly.

Renewable Energy Technologies and Heat Sustainability

The renewable energy sector relies heavily on technologies that can efficiently manage and harness heat energy from various sources such as solar, wind, and geothermal. By utilizing heat-resistant materials, these technologies are able to maximize energy production meanwhile minimizing environmental impact, paving the way for a sustainable future.

Structural Engineering Marvels withstanding Extreme Temperatures

Structural engineers have designed and constructed remarkable buildings and infrastructure capable of withstanding extreme temperatures and environmental conditions. By utilizing heat-resistant materials in their designs, these marvels stand as testaments to human ingenuity and engineering excellence, ensuring durability and safety for generations to come.

Medical Devices: Heat-Resistant Materials in Healthcare Innovations

The healthcare industry has seen significant advancements in the development of medical devices using heat-resistant materials. These materials are essential for ensuring the safety and effectiveness of devices such as surgical instruments and implants, enabling healthcare professionals to provide optimal care to patients at the same time maintaining stringent safety standards.

What are temperature effects on structural materials

Future Trends in Temperature-Resistant Materials Development

Nanotechnology’s Role in Enhancing Thermal Stability

Nanotechnology is revolutionizing the field of materials science by manipulating structures at the nanoscale level, enhancing thermal stability in materials. By engineering materials at the molecular level, researchers can improve their resistance to high temperatures, paving the way for more durable and efficient solutions.

Sustainable Materials for Eco-Friendly High-Temperature Applications

The shift towards sustainability has spurred the development of eco-friendly materials capable of withstanding high temperatures. These materials not only offer thermal resistance but also contribute to reducing the environmental impact of high-temperature applications, aligning with the growing emphasis on green technologies.

Integration of Artificial Intelligence in Temperature Control Systems

Artificial intelligence is being integrated into temperature control systems to optimize thermal performance and efficiency. By leveraging AI algorithms, these systems can adapt to changing conditions in real-time, ensuring precise temperature management and enhancing overall operational effectiveness.

3D Printing Advancements for Customized Heat-Resistant Components

Advancements in 3D printing technology are enabling the production of customized heat-resistant components with intricate designs. This innovation allows for the rapid prototyping and manufacturing of high-temperature materials, offering flexibility and customization options previously unattainable through traditional manufacturing methods.

Collaborative Research Initiatives Driving Material Science Innovations

Collaborative research initiatives among academia, industry, and government entities are driving material science innovations in temperature-resistant materials. By pooling resources and expertise, these partnerships are accelerating the development of cutting-edge materials that push the boundaries of thermal stability and performance.

Expert Insights: Tips for Optimal Temperature Management Practices

Regular Maintenance Protocols for Temperature-Sensitive Equipment

Consistent upkeep is key to the longevity of your temperature-sensitive gear. Just like a well-oiled machine, your equipment thrives on regular maintenance. Neglecting this can lead to a meltdown of disastrous proportions.

Training Programs on Handling High-Temperature Materials Safely

Knowledge is power in terms of handling high-temperature materials. Training programs provide the tools you need to navigate the heat safely. Remember, in the realm of high temperatures, ignorance is not bliss.

Importance of Periodic Thermal Analysis and Testing

Don’t let your equipment play hot and cold with you. Periodic thermal analysis and testing are your best friends in ensuring everything stays at the right temperature. It’s like giving your equipment a regular check-up to catch any fever before it turns into a full-blown illness.

Consulting with Material Science Professionals for Tailored Solutions

When in doubt, seek the wisdom of material science professionals. They are the wizards of the temperature realm, capable of crafting tailored solutions to keep your equipment from breaking a sweat. Remember, a stitch in time saves nine, or in this case, a call to the experts saves you from a fiery disaster.

Implementing Proactive Strategies to Prevent Temperature-Related Failures

Stay ahead of the temperature game by implementing proactive strategies. Prevention is always better than cure, especially touching on temperature-related failures. Think of it as putting on sunscreen before hitting the beach – a little precaution goes a long way.

Conclusion: Harnessing the Power of Temperature Control in Materials

Recap of Key Strategies for Managing Temperature Effects

When navigating the realm of temperature effects on structural materials, it’s crucial to arm yourself with effective strategies. By perceiving thermal dynamics and implementing insulation techniques, you can mitigate adverse impacts and optimize performance.

Encouraging Innovation in Material Science for Enhanced Thermal Performance

In the ever-evolving landscape of material science, innovation is key to exposing enhanced thermal performance. By probing advanced composites and novel alloys, researchers can push boundaries and revolutionize temperature control in structural materials.

Empowering Industries with Knowledge to Overcome Temperature Challenges

Industries grappling with temperature challenges can benefit greatly from knowledge empowerment. Equipping professionals with insights on heat transfer mechanisms and thermal conductivity fosters informed decision-making and bolsters resilience against temperature-induced issues.

Embracing Continuous Learning and Adaptation in the Face of Changing Conditions

Adaptation is the cornerstone of effective temperature management. Embracing a culture of continuous learning enables professionals to stay ahead of the curve, adjusting strategies and materials in response to changing environmental conditions and temperature fluctuations.

Inspiring a Culture of Resilience through Effective Temperature Management

Effective temperature management isn’t just about control—it’s about fostering resilience. By instilling a culture that values proactive monitoring, rapid response to temperature variances, and the implementation of robust mitigation measures, industries can cultivate a spirit of resilience that withstands the heat.