Introduction to Industrial HVAC Systems

Industrial HVAC systems are the unsung heroes of large facilities, ensuring optimal working conditions for machinery and personnel alike. These systems are the heartbeat of industrial operations, regulating temperature and air quality with precision.

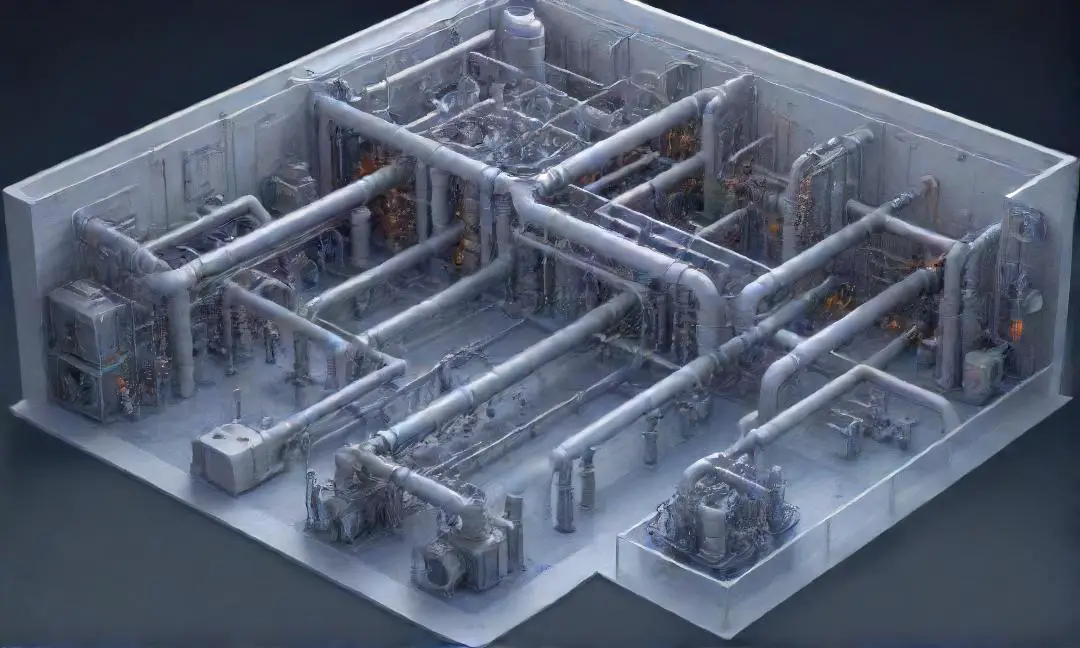

Components of Industrial HVAC Systems

Cognizing the Role of Compressors

Compressors are the powerhouse of HVAC systems, responsible for pressurizing refrigerant gas to cool the air. Think of them as the muscles that flex to keep the system running smoothly, maintaining the perfect balance of temperature control.

The Importance of Evaporator Coils

Evaporator coils are the cool cats of the HVAC world, where the magic of cooling happens. These coils work their wizardry by absorbing heat from the air, transforming it into a refreshing breeze that circulates throughout the facility.

Investigating the Function of Condenser Units

Condenser units are the unsung heroes that bring balance to the force of industrial HVAC systems. They release the heat absorbed by the evaporator coils into the outside air, completing the cooling cycle with finesse and efficiency.

Energy Efficiency Tips for Industrial HVAC Systems

Importance of Energy Efficiency in HVAC Systems

Efficient energy usage in industrial HVAC systems is crucial for cost-saving and environmental sustainability. By optimizing energy consumption, businesses can reduce operational expenses and minimize their carbon footprint.

Optimizing Thermostat Settings

- Setting Temperature Zones Strategically

Dividing the workspace into temperature zones allows for targeted heating and cooling, optimizing energy usage based on specific needs in different areas. This strategic approach ensures efficient operation of the HVAC system.

- Utilizing Programmable Thermostats

Programmable thermostats enable businesses to schedule temperature adjustments based on occupancy patterns and operational hours. This automation helps prevent unnecessary energy consumption during off-peak times, improving overall efficiency.

Regular Maintenance Practices for Energy Conservation

Maintaining industrial HVAC systems regularly is essential for ensuring optimal performance and energy efficiency. Scheduled inspections, filter replacements, and cleaning of components help prevent energy wastage and prolong the lifespan of the system.

Troubleshooting Common Issues in Industrial HVAC Systems

Identifying Airflow Restrictions

Picture this: your industrial HVAC system is struggling to circulate air efficiently, leading to discomfort and inefficiency. Identifying airflow restrictions is crucial in restoring optimal performance. Check for clogged filters, blocked vents, or damaged ductwork as potential culprits.

Addressing Refrigerant Leaks

Refrigerant leaks can throw a wrench in your HVAC system’s operation, causing it to underperform and consume more energy. Recognizing signs such as hissing sounds or ice buildup is the first step. Take swift action to prevent further damage and ensure safety.

- Signs of Refrigerant Leaks

Spotting a refrigerant leak early can save you from a major cooling crisis. Keep an eye out for decreased cooling efficiency, higher energy bills, or an inexplicable rise in indoor humidity.

- Steps to Handle Refrigerant Leak Issues

When faced with a refrigerant leak, don’t sweat it. Reach out to a professional technician to locate and repair the leak promptly. Remember, refrigerants are harmful to the environment, so proper containment and disposal are vital.

Dealing with Electrical Component Failures

Imagine your HVAC system suddenly going silent, leaving you in the heat—literally. Electrical component failures can disrupt your system’s operation. Stay vigilant for warning signs like tripped breakers, flickering lights, or unusual noises.

Enhancing Indoor Air Quality with Industrial HVAC Systems

Comprehending the Impact of HVAC Systems on Indoor Air Quality

Picture this: your industrial workspace, a bustling hive of activity, with HVAC systems silently working in the background to ensure the air you breathe is clean and fresh. These systems play a crucial role in maintaining indoor air quality, filtering out pollutants and contaminants, creating a healthier environment for all.

Importance of Proper Ventilation

- Ever thought about the air you breathe at work? Proper ventilation is like a breath of fresh air for your workspace, ensuring a constant flow of clean air in the course of expelling stale, potentially harmful air. It’s the secret ingredient to a productive and healthy work environment.

Ventilation Strategies for Improved Air Quality

Let’s talk strategy. Ventilation isn’t just about moving air around; it’s about strategic airflow management. By utilizing a mix of natural and mechanical ventilation techniques, industrial HVAC systems can optimize air circulation, reducing indoor pollutants and maintaining a fresh atmosphere.

Benefits of Air Filtration Systems

- Think of air filtration systems as the unsung heroes of indoor air quality. These systems work tirelessly behind the scenes, trapping dust, allergens, and other particles that can compromise air quality. With high-efficiency filters in place, you can breathe easy knowing your workspace is free from harmful airborne contaminants.

Upgrading Your Industrial HVAC System: A Comprehensive Guide

Signs It’s Time to Upgrade Your HVAC System

If your industrial space feels like a sauna in summer and an icebox in winter, it might be time to consider upgrading your HVAC system. Unusual noises, frequent breakdowns, and rising energy bills are clear indicators that your system needs an overhaul.

Choosing the Right HVAC System for Your Industrial Space

- Factors to Consider When Selecting a New System

When selecting a new HVAC system for your industrial space, size does matter. Ensure the system is appropriately sized to meet the demands of your facility. Additionally, consider the system’s efficiency, maintenance requirements, and compatibility with your existing infrastructure.

- Investigating Energy-Efficient Options

In today’s eco-conscious world, energy efficiency is paramount. Investigate energy-efficient HVAC options that can help reduce your carbon footprint and lower your utility bills. From smart thermostats to variable refrigerant flow systems, there are several innovative solutions available to optimize energy usage in your industrial setting.

Maximizing the Lifespan of Your Industrial HVAC System

1. Importance of Regular Maintenance

Just like a well-oiled machine, your industrial HVAC system requires regular maintenance to keep it running smoothly. Neglecting maintenance can lead to costly breakdowns and disruptions to your operations. By staying proactive with maintenance, you can catch potential issues early and ensure your system operates at peak efficiency.

2. Scheduling Professional Inspections

As for the health of your industrial HVAC system, nothing beats the expertise of a professional inspection. These inspections are like a doctor’s check-up for your system, identifying any underlying issues before they escalate into major problems that could halt your operations. Regular inspections not only save you money in the long run but also provide peace of mind knowing your system is in top condition.

- a. Benefits of Routine Check-ups

Regular routine check-ups are the cornerstone of a healthy industrial HVAC system. These check-ups help detect and address minor issues before they snowball into major headaches. By investing in routine maintenance, you are investing in the longevity and efficiency of your system, ultimately saving you time and money in the future.

- b. Extending the Lifespan of HVAC Components

Each component of your industrial HVAC system plays a crucial role in its overall performance. By extending the lifespan of these components through regular maintenance and inspections, you are ensuring that your system operates at its best for years to come. Think of it as giving your HVAC system a new lease on life, allowing it to work tirelessly for your business without missing a beat.

How do industrial HVAC systems work

Industrial HVAC systems are complex machines that regulate temperature, humidity, and air quality within large commercial spaces. These systems work by drawing in air, cooling or heating it through various components like compressors and evaporators, and then distributing the conditioned air throughout the building via ductwork. Absorbing how these systems work is essential in maintaining and optimizing their performance to ensure a comfortable and productive environment for your employees and customers.